SHEET BENDING ROBOTIC

With the 6-Axis robots and servo-controlled fully automatic machine bending stations, we have transformed the operations carried out with operator feeding at the sheet bending stations to be much safer and more efficient. With the prescriptions prepared once for robot and bending station, production of tens or even hundreds of products can be started immediately.

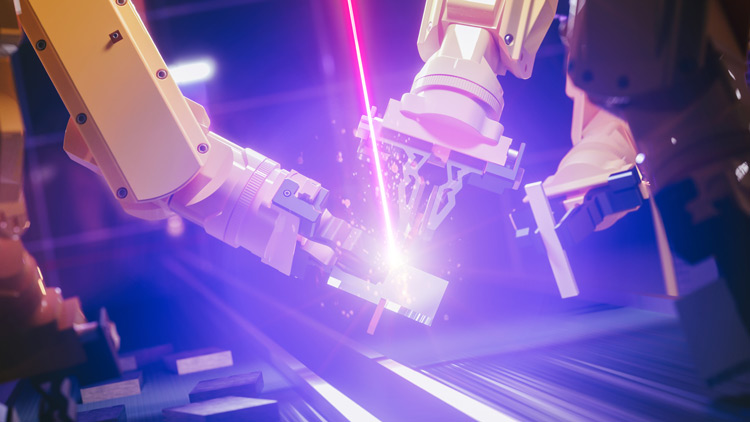

LASER WELDING

Laser welding centre especially provides maximum contribution to occupational health and safety with the controlled absorption and removal of toxic gases and eye threatening rays that arise from the welding process in a cabinet.

In addition to all these, with the programming feature of servo-controlled positioners and 6-Axis robots for standard parts, it decreases the necessity of having qualified personnel at all times and allows the system to become operational by selecting the required recipes with a click. Therefore, by allowing the establishment make faster production 24/7, the standardisation of production in every shift is ensured.

SPOT WELDING

As the semi-automatic spot welding systems prevent occupational accidents, they give establishments the chance to produce standard products much faster than hand torches.

SEALER APPLICATIONS

Sealing applications, which is one of the most important processes in mounting technologies are transferred to robots from humans.

With this application, by eliminating the “damage to human life” of the chemicals used in sealing processes, at the same time, it is possible to prevent human errors and waste as well as to ensure much faster and sensitive production at lower costs.